Application of electric heating cable for freezing protection and heat preservation of the fire pipe network in the ammonia zone of the power plant

Published on:

2023-03-01 13:02

At present, the largest application of liquid ammonia in thermal power plants is a liquid ammonia denitrification system as a reducing agent, which is used to remove nitrogen oxides, namely NOX, in the flue gases of boiler combustion products, reduce atmospheric emissions, and protect the environment.

Liquid ammonia is usually stored and transported in liquid ammonia storage tanks. It is easy to harm the environment and human body when liquid ammonia leaks, so special attention should be paid. Therefore, it is necessary to pay special attention to the problem of freezing of liquid ammonia storage tanks.

Icing of liquid ammonia storage tanks usually occurs at three locations:

1. Pipeline freezing: The pipeline between the liquid ammonia control valve and the evaporator freezes due to the liquid ammonia gasifying and absorbing heat in large quantities, and the temperature drops rapidly. Water molecules in the air are condensed on the pipeline and freeze. In

2. The pressure gauge freezing on the neck of the cylinder: After long-term transportation, the liquid level sensor at the top of the tank with low-temperature liquid ammonia and the position of the tank joint will be loose. When the tank is not used, but after its use, a large amount of ice will appear. In

3. Icing in the storage tank: Icing inside the storage tank is mainly due to the heat exchange between the inside and outside of the liquid ammonia tank and the condensation of water vapor in the air.

Abnormal freezing of the exhaust pipe of the vaporizer or the shell of the liquid ammonia storage tank and other possible parts must be dealt with in a timely manner, and the hidden hazards must be addressed to solve the problem or replaced or handled safely. The ammonia zone of the power plant is where the power plant stores liquid ammonia to prevent leakage of liquid ammonia. A complete fire pipe system will be set up in the liquid ammonia storage area. To ensure normal operation of fire extinguishing pipelines and prevent freezing and clogging at low temperatures in winter, they require electric heating and insulation.

The water in the fire-fighting pipeline is stationary. Compared to the general water supply, the water in the fire network in winter freezes more often. Even in East China, where winter temperatures are relatively mild, outdoor temperatures will be below freezing in winter, but there is also a possibility that the static fluid in the pipeline could freeze.

The principle of antifreeze technology for the electric heating of the fire pipe is to attach the heating cable to the outside of the pipe to generate electricity, transfer the heat of the liquid in the pipe, and interact with the outer insulation layer of the pipe for compensation. And maintain the temperature of the liquid in the pipe to achieve the calculated temperature level. The purpose of antifreeze for fire-fighting water supply facilities is to prevent the water in the pipe from freezing into the ice, so the electric heating cable is only needed to maintain the water temperature in the object above 0 ° C.

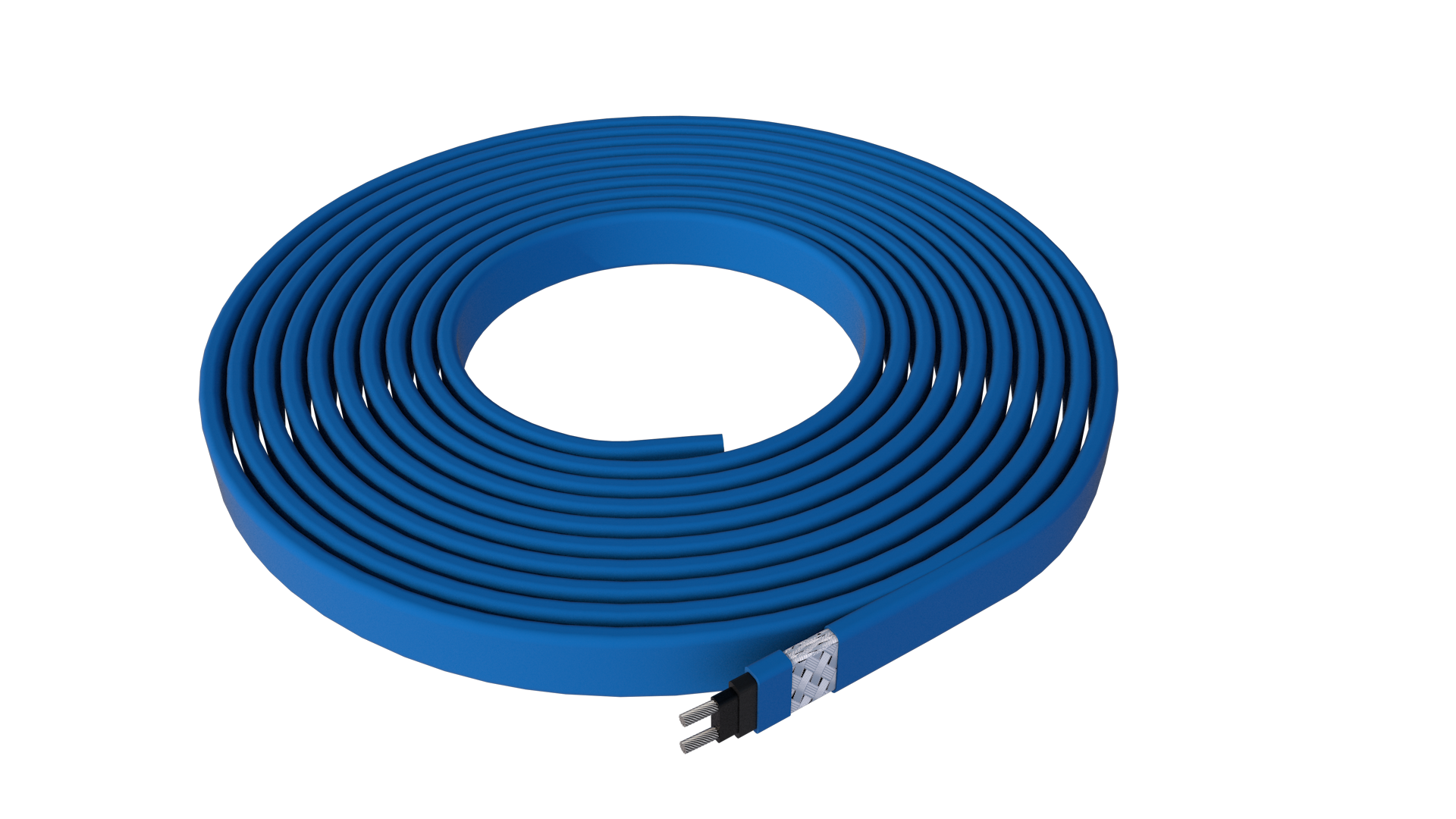

Low temperature self-regulating electric heating cable and self-limiting temperature electric heating cable, the heating cable is in the shape of a strip with a width of more than 11mm, which can cling to the surface of the pipeline and use electrical energy for heating. The environment in the spraying pipeline to keep warm. It plays the role of keeping heat and antifreeze for a short time. In addition, the electric heating belt also has advantages such as easy installation, easy maintenance, 24-hour maintenance, high automation, low operation and maintenance costs, etc. D., has good economic and social advantages, and is very suitable for large-scale increase.

Previous Article

Latest News