Application of self-regulating low temperature electric heating cable in printing

Published on:

2022-12-29 16:22

In printing plants, there are situations where viscous liquids such as ink and glue need to be transported through thermal insulation pipes. In these cases, the pipeline often operates intermittently, and the liquid does not drain, the temperature control accuracy is low, and the power is not very large. In the past, these printing and binding tubing machines used conventional heating wires, and a temperature sensor was used to detect and control the temperature. However, in the process of use, the thermoregulator will be lost and the heating wire will burn out, which will bring inconvenience in use and maintenance.

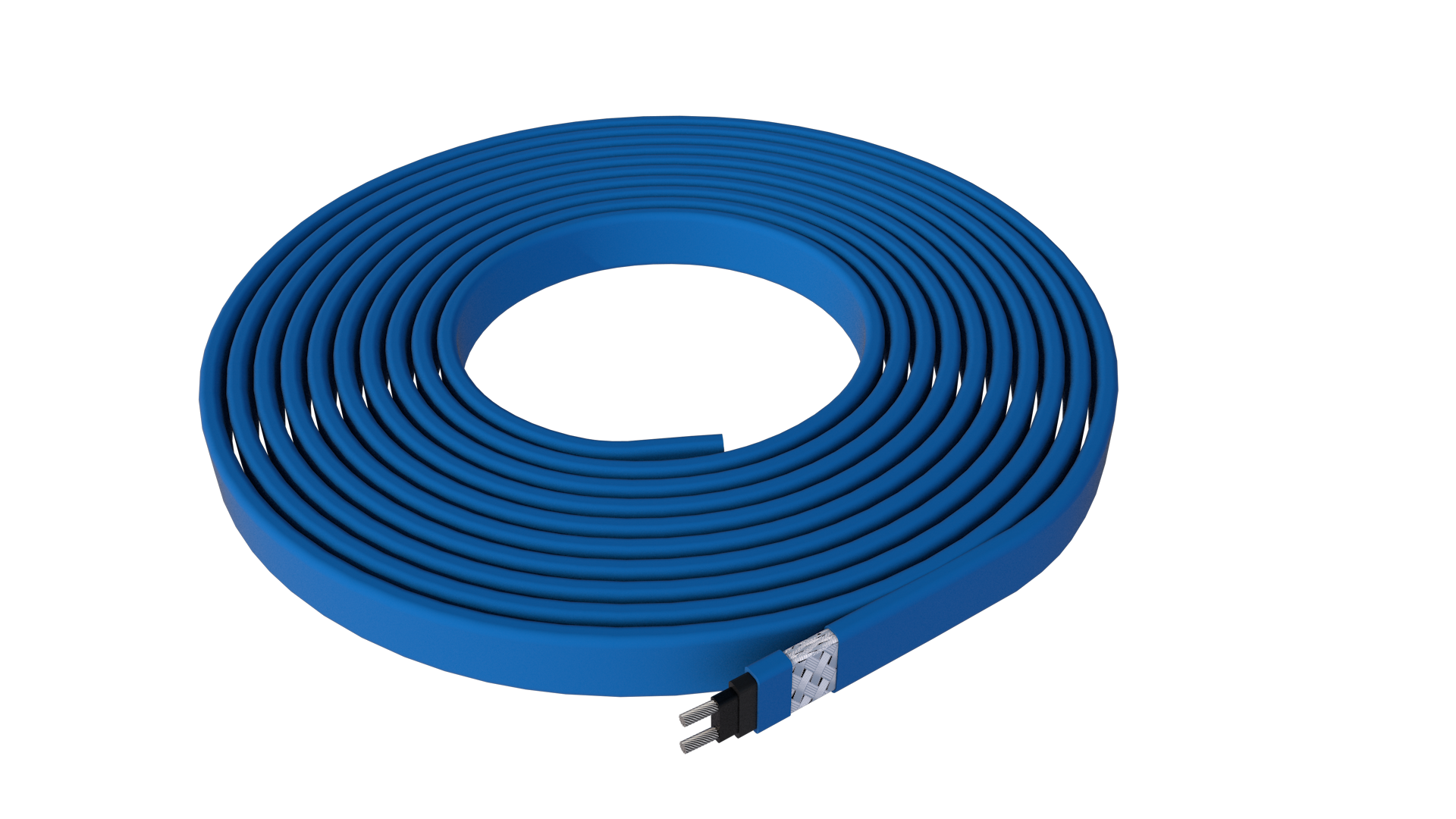

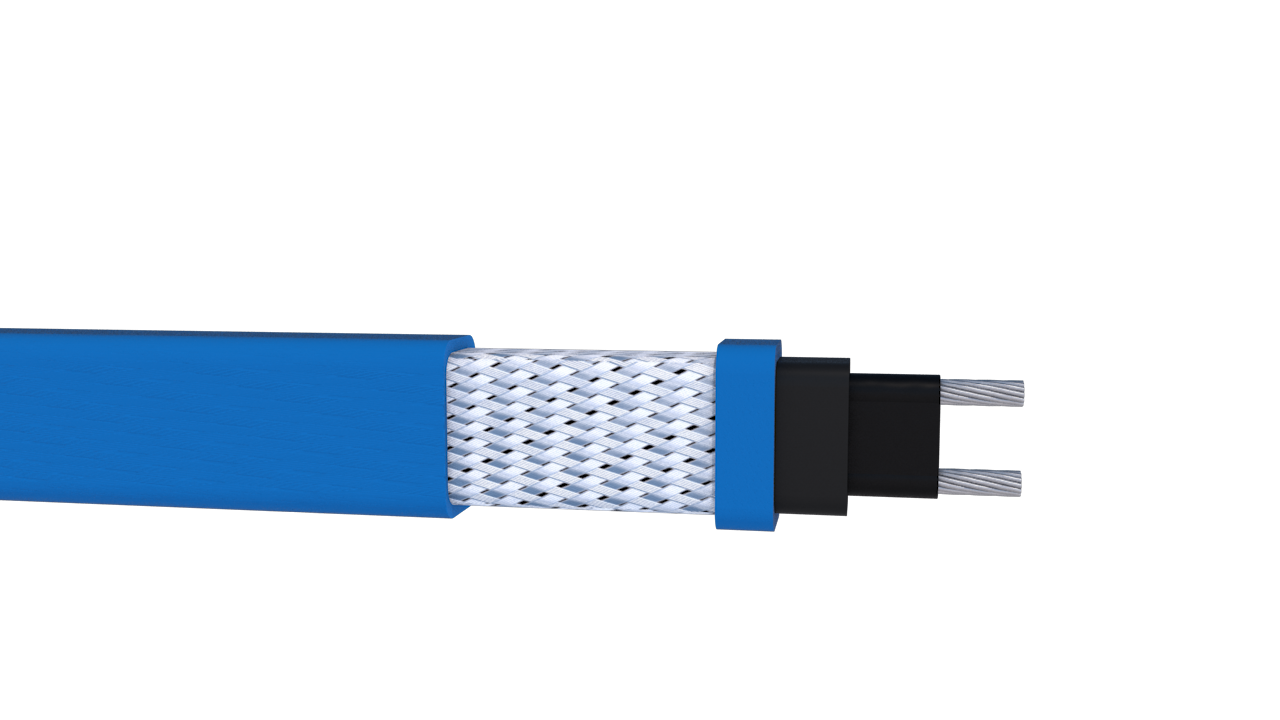

With the increasing popularity of electric heating tapes, the use of self-regulating electric heating tapes in the printing industry is becoming more and more common. The structure of the self-regulating electric heating belt is composed of wire core, core belt, insulation, protective layer, shell and other parts. Compared with similar domestic products, our self-regulating electric heating cable has the advantages of small starting current, good memory performance, low annual attenuation rate and long service life.

Generally speaking, the use of self-regulating low-temperature series in the printing industry is quite satisfactory. The maximum operating temperature of the self-regulating low temperature electric heating belt is 65 ± 5 °C, and the starting current is ≤ 0.5 A/m; the self-regulating electric heating belt can be arbitrarily shortened or lengthened for a certain range and multiple crossovers are allowed. And do not worry about high temperature hot spots and fire, and the self-regulating motor is easy to install, Easy to maintain and provide 24-hour service, high level of automation, and low maintenance and maintenance costs.

The practice of many printing plants has proved that the control of the temperature of the conveyor pipe with the DWK electric heating belt fully meets the operating requirements, and the power consumption is only 10-20% of the original product.

Latest News