Design solutions of the electric heating system of fire-fighting water supply facilities

Published on:

2022-12-30 10:59

Winter temperatures in the north are often below 0 °C, and in mountainous areas even below-30 °C. When the temperature drops in winter, the phenomenon of freezing and expansion of water in the pipeline can occur, and if there is a fire at this time, the consequences will be catastrophic. Therefore, it is very important to add thermal insulation to fire pipes in winter. Electric heating is more and more recognized in antifreeze and cold insulation because of its advantages.

Constructive antifreeze solutions for fire water supply facilities: The purpose of antifreeze for fire water supply facilities is to prevent freezing of standing water stored inside, cracking of objects, and also to increase the guarantee of fire safety in the cold winter seasons. Thus, the function of the fire-fighting heating cable is to maintain the water temperature in the object above 0 °C. National water supply design standards require that the water temperature in the water supply is at least 4 ° C.

The function of the DWK heating cable is to maintain the water temperature in the facility above 0 °C.

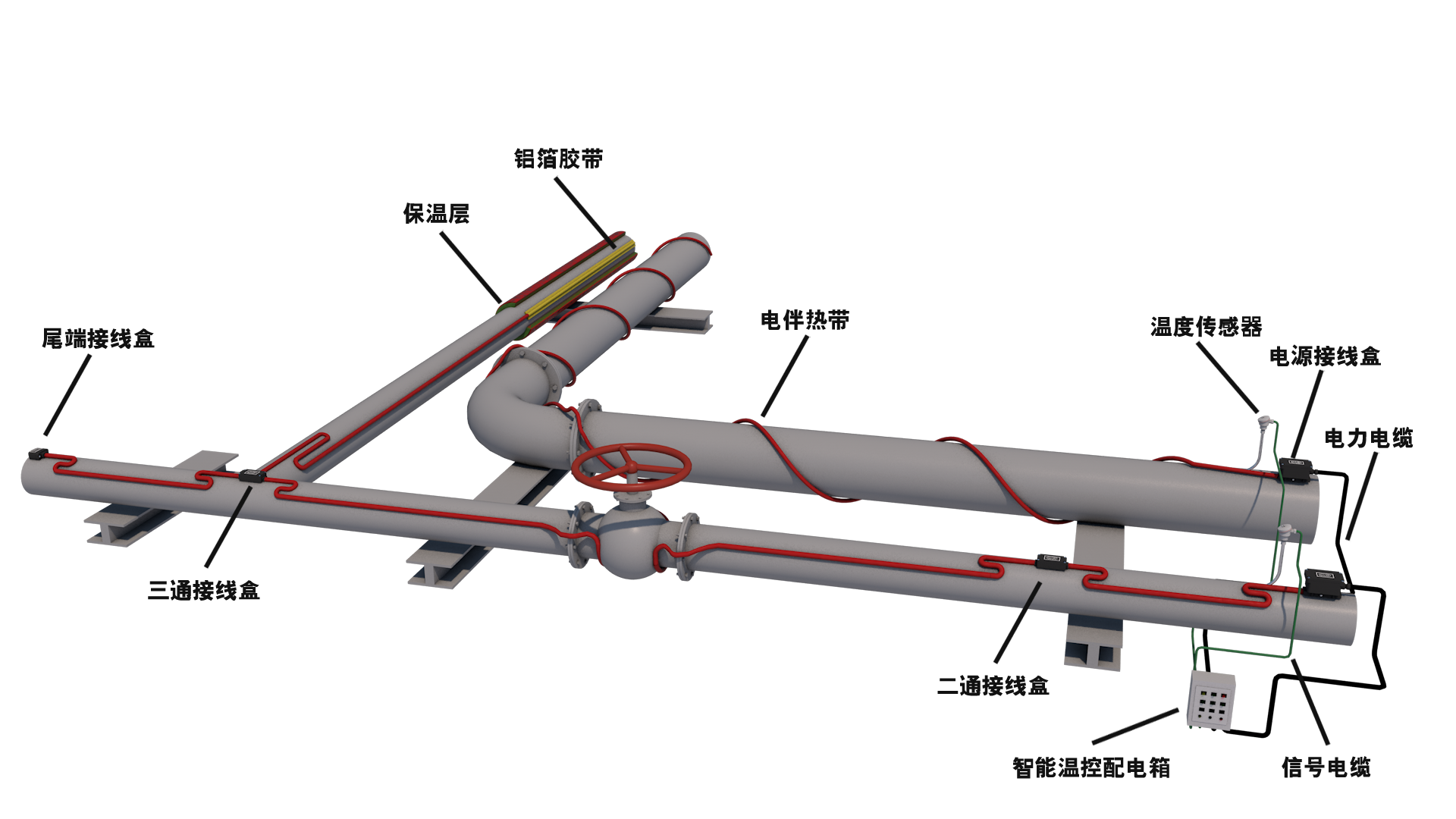

Constructive idea of an electric heating system: The purpose of introducing an electric heating system is to prevent freezing of standing water poured into fire water supply facilities and damage to equipment. In order to improve fire safety in winter. Therefore, the function of electric heating is to maintain the water temperature in the object in the range from 0 ° C to 5 ° C, which does not guarantee the normal operation of the fire pipeline. Calculate the maximum heat dissipation according to the thickness and thermal conductivity of the outer insulation layer, the pipe diameter, the outer diameter of the object and the average value of the local minimum low temperature, and then select the type and method of installation of the electric heating cable according to the heat dissipation.

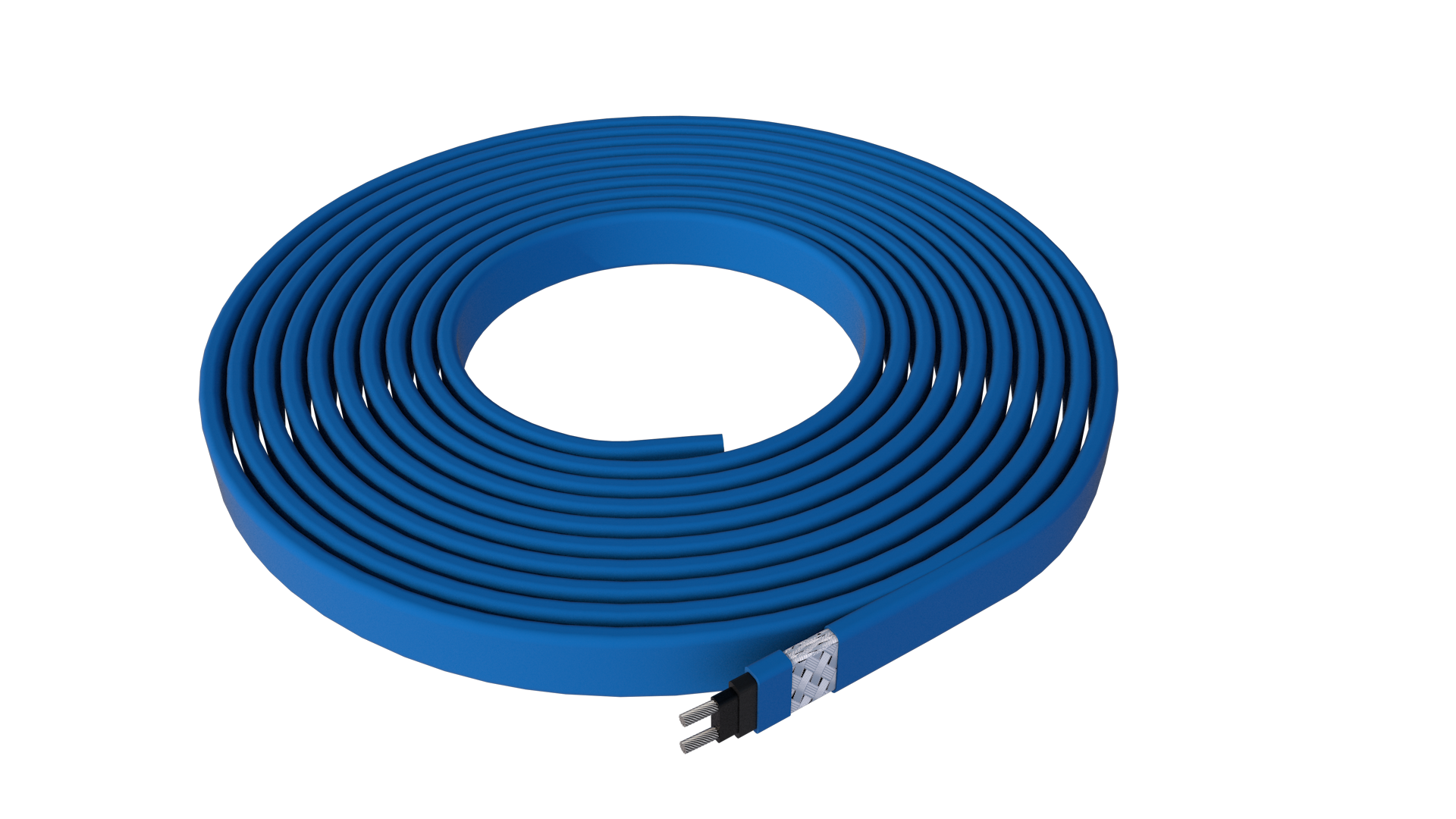

Cables used in an electric heating system come in two types: self-regulated temperature heating cables and constant power heating cables. Using a self-regulating electric heating cable, one can see how an electric heating cable acts on the fire extinguishing pipeline. The self-regulating electric heating cable can be tied to the outside of the fire extinguishing pipeline. When the system is running, the current is turned on to warm up, interact with the external insulation layer of the pipeline, and then release the heat solution in the pipeline, compensate and maintain the temperature of the liquid in the fire extinguishing pipeline to the design temperature level. In the process of installation, the self-regulating electric heating cable should be uniformly wrapped with fire fighting equipment, such as pipes, valves, fire hydrants, foaming tanks, etc. D., and one end should be connected to the thermostat to accurately control the operation of the self-regulating electric heating cable. The temperature controller of the heating cable is used to limit the temperature of the outer surface of the pipe. When the temperature of the detection point is lower than the set value, the thermostat will start immediately, and the electric heating system with self-control temperature will start to maintain the temperature of the pipes, fittings and fire-fighting equipment. When the temperature sensor detects that the temperature of the pipeline is higher than the set temperature, the thermostat shuts off the power supply so that the electric heating system with self-temperature control can operate in the most economical state and meet the temperature requirements. Fire pipeline insulation project.

If the laying distance of the fire-fighting pipeline is large and the pipeline is required to maintain a constant temperature, a constant power electric heating cable is used when selecting the equipment.

Latest News