Application of serial cables for constant power electric heating in electric heating and maintaining temperature in large crude oil storage tanks

Published on:

2022-11-07 11:34

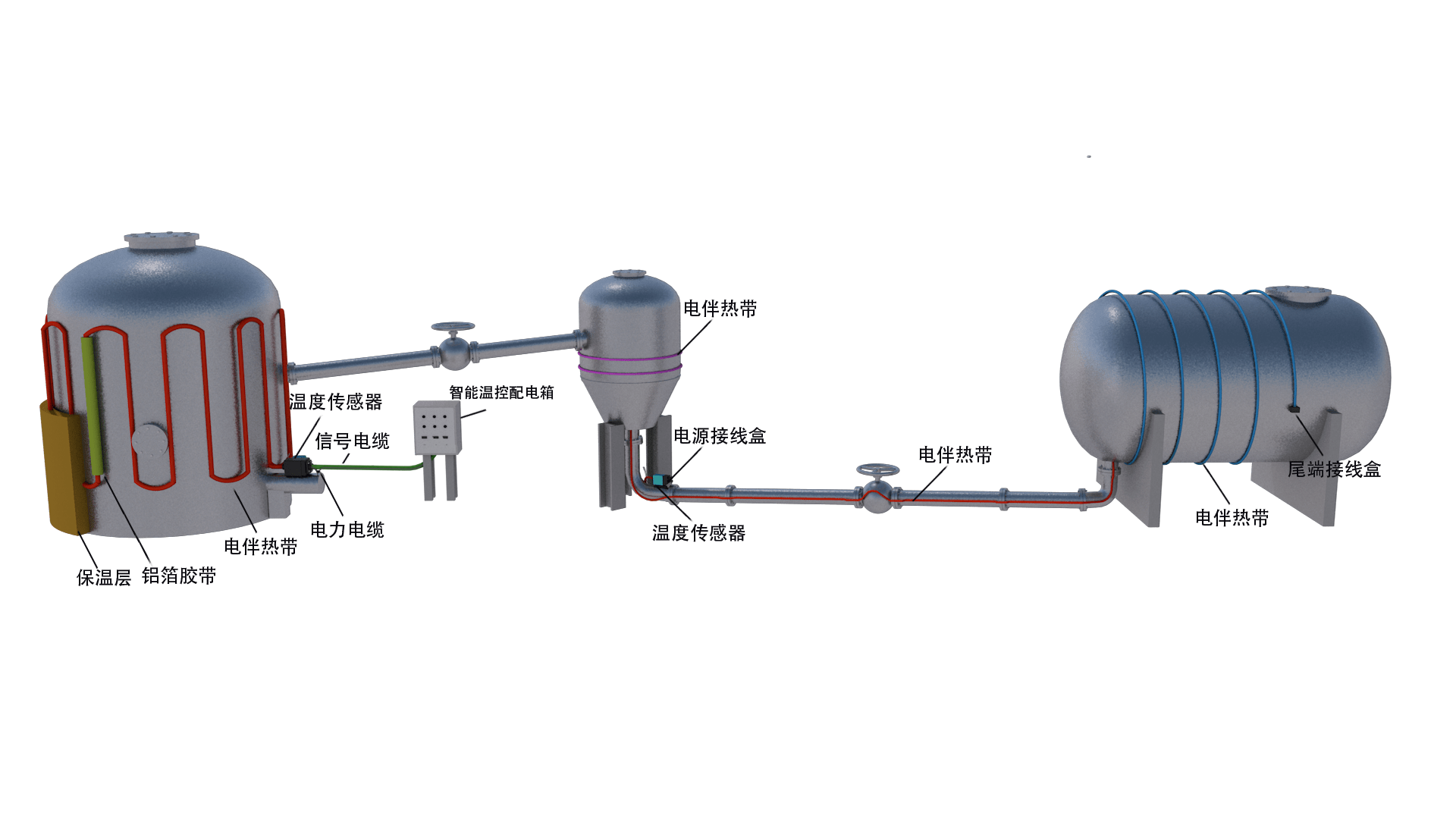

Electric heating and temperature maintenance in large crude oil storage tanks mainly consists of winding electric heating cables around the outer wall of storage tanks and using electric heating cables to heat oil in storage tanks to maintain temperature and heat. Compared with traditional hot water or steam heating, the electric heating method has the advantages of simple installation, uniform heating, accurate temperature control, water saving, high heat exchange efficiency, long service life, no environmental pollution, design, installation and maintenance. Small and other advantages, because the new generation heating technology after steam heating and hot water heating is widely used.

The electric heating system for maintaining the temperature of the tank is mainly composed of electric heating cables, temperature measurement devices, power distribution boxes, electric heating connectors and related accessories. The temperature detection device is used to determine the temperature of the tank surface and transmit the temperature signal to the temperature controller. When the detected temperature value is lower than the set temperature, the electric heating will automatically start through the control system, otherwise the power will be automatically turned off to stop the electric heating.

Constant power electric heating belt can be divided into single-phase, two-phase and three-phase according to the working voltage, and parallel and series types according to the working principle. The maximum use length of the serial electric heating belt is longer, the heating range is larger, and the electric heating power circuit is smaller.

In 2018, we used our constant power electric heating cable to prevent freezing for electric heating and maintain the temperature of two new floating-roof oil tanks on the line for a crude oil pipeline heating reconstruction project at Daqing Oil Field. The average temperature of the coldest month in the area is-30 °C and the extreme minimum temperature is-50 °C. The insulation material of the tank is 100mm thick composite magnesium aluminosilicate, the freezing temperature of the storage medium is 25 ° C. The oil tank should maintain a temperature above 3 °C.

After more than four years of operation, our electric heating products are still in good condition. Each year, the liquid level in each storage tank drops below 4.5 m for about 200 days, and the operating cost of each storage tank is about 480,000 euros. Yuan/year The operating costs of the two storage tanks have been saved up to 960,000 yuan/year in four years.

Our electric heating cables provide good social and economic benefits for the maintenance and energy saving of the entire oil pipeline.

Latest News