Electric heating cables commonly used for thermal insulation of tunnel water supply fire pipes in cold regions.

Published on:

2022-08-29 16:52

In the northern cold region, the high-speed tunnel fire protection system uses a water fire protection system as the main mode of operation and a dry powder fire extinguisher as an additional mode of operation. The tunnel fire protection system reaches the entrance of the tunnel. Due to the method of insulating the protective layer, the pipe network in the tunnel often freezes and crackles during winter operation.

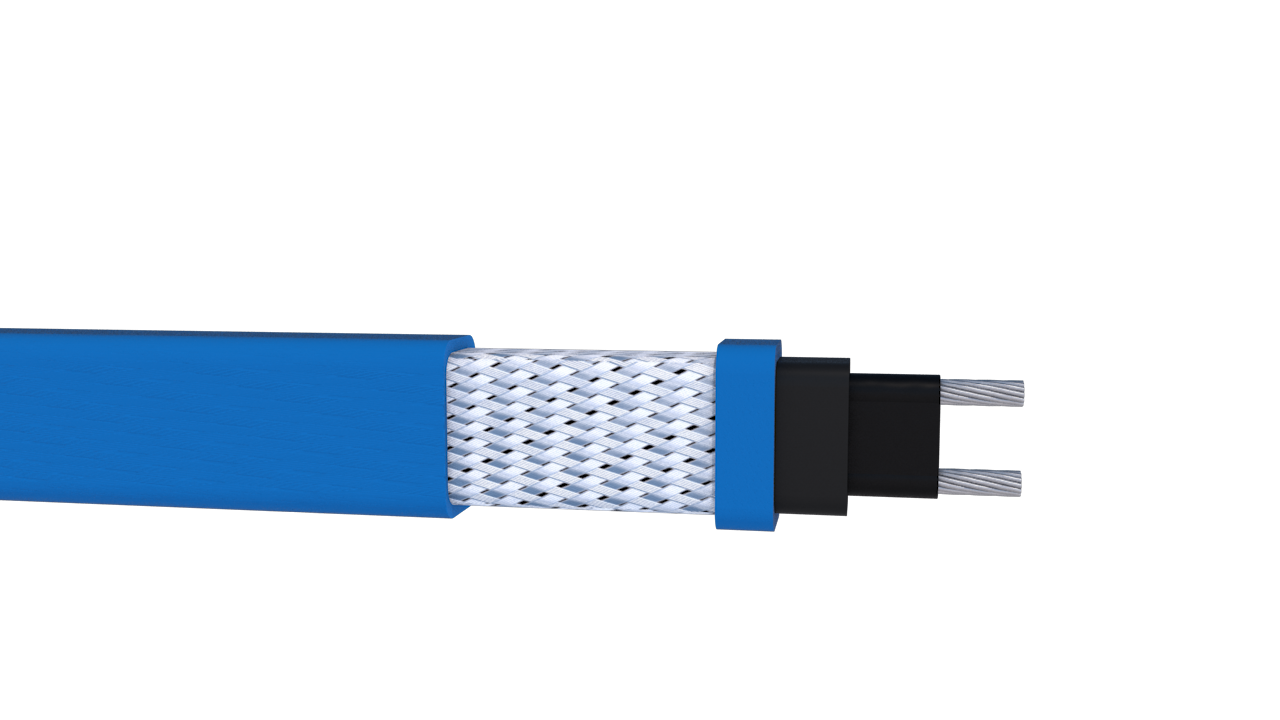

Electric heating technology is a technology in which electric heating cable materials are used to heat and insulate fire extinguishing pipelines, and electrical energy is used to ensure that electric heating cables continuously generate heat on the surface of an insulated pipeline. Electric heating cables in the form of parallel single, parallel double, winding, etc. D. At that time were only included in insulated pipes and valves. The purpose of heat preservation and freezing protection is to generate heat after the power is turned on, use the generated heat to heat the environment in the fire extinguishing pipeline, make up for the heat loss caused by the temperature difference inside and outside the pipeline shell, and maintain the temperature. The effects of melting and melting ice, antifreeze and heat preservation achieved the goal of preserving antifreeze and heat for fire protection pipelines. The electric heating system mainly consists of power supply, electric heating cable, thermostat (constant power electric heating cable), thermostat (self-regulating electric heating cable), distribution box, double-sided, three-sided, tail and other accessories.

HCL Series type heater

HCL series electric heating tape is a type of electric heating with a wire core as a heating element. Since the resistance per unit length of the wire core and the passing current are constant, the entire heating tape is heated evenly from end to end., and the output power is constant. Its biggest feature is its long length of use, which is mainly suitable for heating and heat preservation of single pipelines of long and ultra-long length. The maximum length of the power point is from several hundred meters to several thousand meters.

HCL Series Electric Heating Belt Parameters

Low Temperature Self-control Electric Heating Belt

Low temperature self-regulating electric heating belts are widely used in civil solar power, geothermal heating, fire, petroleum, chemical, steel, electric power, environmental protection and other industrial enterprises. Coagulation and antifreeze.

Parameters of low temperature self-regulating electric heating belt

(1) Standard color: black/blue

(2) Temperature range: The maximum operating temperature is 65 ± 5 °C and the maximum sustained temperature is 90 °C.

(3) Design temperature: Polyolefin minimum-20 °C, Fluorine material minimum-60 °C

(4) Start current: ≤ 0.5 A/m

(5) Thermal stability: After the electric heating belt has passed the thermal performance test, its power should be maintained at 90% of the original value.

(6) Bending radius: 25.4mm at-20 °C, 35mm at-60 °C

(7) Insulation resistance: The insulation resistance between the electric heating conductor and the metal shielding layer shall not be less than 50 MOM.

Next Article

Latest News