Design principles of electric heating and thermal insulation of the metro

Published on:

2023-03-29 10:31

The Metro not only increases the convenience of travel for citizens, but also plays a very important role in expanding the radius of movement of people. The normal operation of the subway is inseparable from the safety of the fire pipeline. In the cold winter, the fire-fighting pipeline without antifreeze measures often freezes. Great hidden danger. Currently, drainage pipes and fire-fighting pipes at subway stations and tunnel entrances use electric heating to prevent freezing and keep warm.

At present, our products work well in Jinan, Tianjin, Shijiazhuang and other projects. We have summarized the design principles for electric heating and metro insulation and shared them with design departments and colleagues.

In the station's air ducts, fire-prevention pipes and water pipelines at entrances and exits, domestic water supply pipes, electric heating and heat preservation systems are installed with dual power sources.

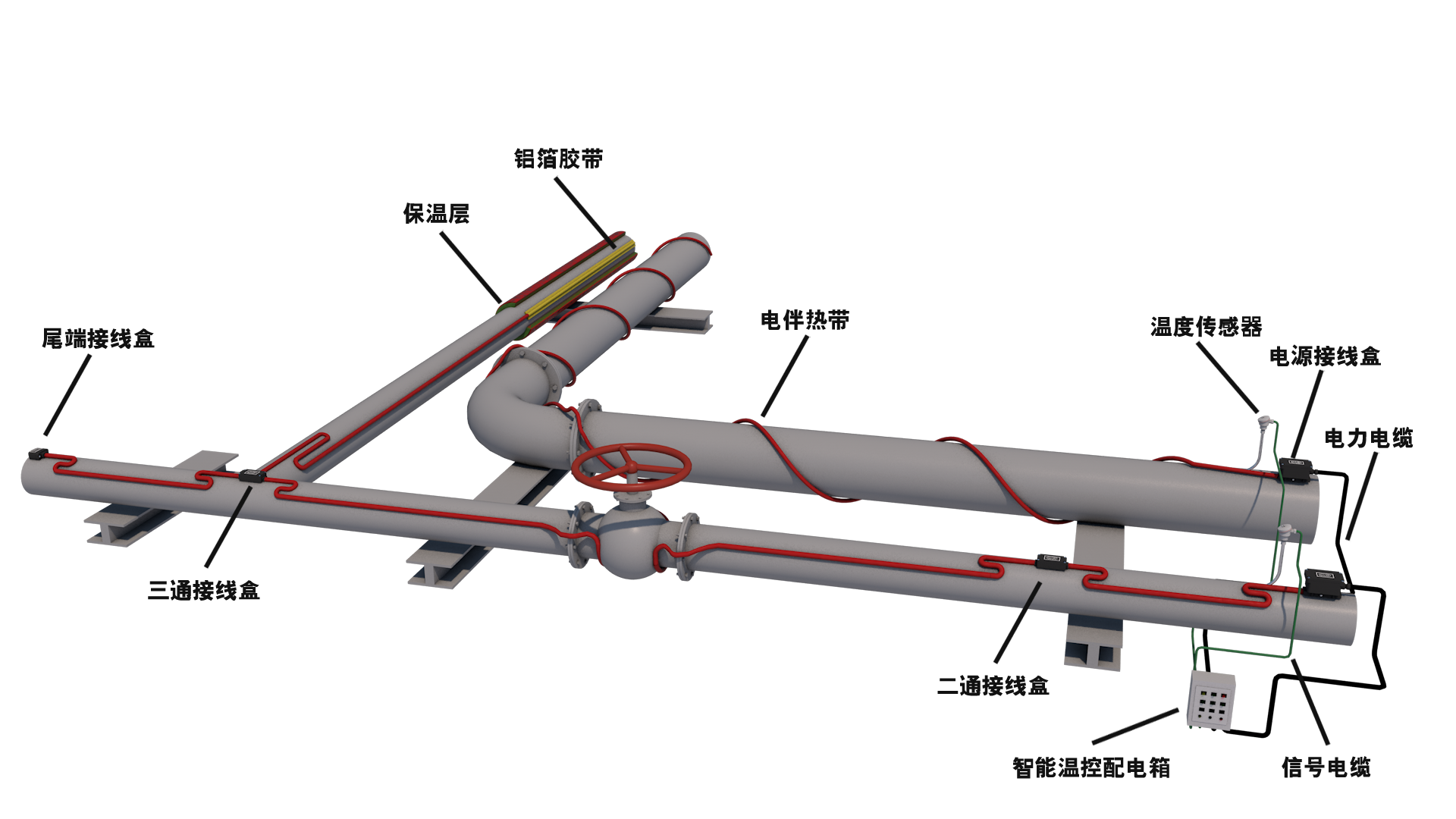

The power supply system consists of a low-voltage switchboard power switch, a bridge transmission and distribution line and an electric heating control cabinet. According to each heating circuit of the electric heating cable, the electric heating control unit should be equipped with air switch, leakage switch, detection system or intelligent control system and other devices. Among them, the detection system is used to determine the operating temperature of the heated pipeline. When the temperature of the pipeline detected by the temperature sensor is lower than the set temperature of the detection system (usually 5 °C), the heating cable control system is automatically turned on and heated, otherwise it will automatically turn off to stop the heating.

Each electric heating control unit is equipped with an automatic alarm controller that monitors each cable heating circuit in the unit in real time according to the specific situation, including the ultra-high temperature alarm. Ultra-low temperature alarm, temperature measurement failure alarm, sensor failure alarm, heating cable disconnection, leakage alarm, overcurrent and electric heating pipeline operation.

The temperature control unit monitors 4-6 pipes at the same time: The setting principle of the temperature sensor is as follows: Each set of the control unit is equipped with 1 ambient temperature sensor, and each pipe is equipped with 2 temperature sensors that are placed on relatively unfavorable points of the entire pipeline. Each electric heating control unit is equipped with an automatic alarm controller that monitors each cable heating circuit in the unit in real time according to the specific situation, including ultra-high temperature alarm. Ultra-low temperature alarm, temperature measurement failure alarm, sensor failure alarm, heating cable disconnection, leakage alarm, overcurrent and electric heating pipeline operation.

The temperature control unit monitors 4-6 pipes at the same time: The setting principle of the temperature sensor is as follows: Each set of the control unit is equipped with 1 ambient temperature sensor, and each pipe is equipped with 2 temperature sensors that are placed on relatively unfavorable points of the entire pipeline.

Latest News