Electric heating system of main pipelines of highly aromatic oil

Published on:

2023-01-11 14:10

In petrochemical plants, the various pipelines and equipment shall generally operate at a certain maintenance temperature (above ambient temperature, a certain temperature reached by the medium or process material at equilibrium under given design conditions). Due to the loss of heat, if the pipeline or equipment is only isolated, its temperature will drop to ambient temperature. Therefore, in order to compensate for the heat loss in the transmission process, it is necessary to install a heating pipe or heating cable on the outer wall of the transmission pipe to compensate for heat loss.

In the high-aromatic oil trunk pipeline, electric heating technology is commonly used to maintain the environment temperature in the pipeline during operation and shutdown. The electric heating is to use electric heat to supplement the heat lost by the heated object during the production process and to maintain the most suitable temperature of the process environment. The goal is to prevent freezing, prevent the environment from dissipating heat into the environment, maintain the process temperature, and reduce the viscosity of the environment.

The high-aromatic oil pipeline of a large petrochemical plant in East China has a total length of 5000 m. Due to the limited power supply points at both ends of the pipeline, a complex of automatic control systems for electric heating was installed. Electric heating products include self-regulating electric heating cables, constant power electric heating cables, surface effect electric heating cables, snow melting heating cables, mineral insulated heating cables, etc. D. Currently, electric heating cables, commonly used in high aromatic oil pipelines, are serial constant power electric heating cables and self-regulating electric heating cables. Due to the fact that the high-aromatic oil pipeline of the plant has an electric heating length of up to 5800 meters, the use of serial electric heating of constant power, more suitable for main pipelines, was chosen.

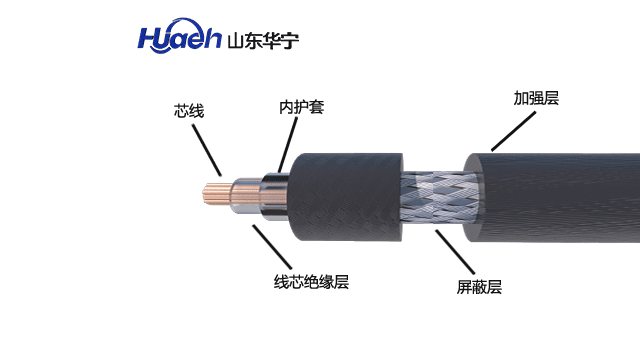

HCL series electric heating belt is a kind of electric heating product with a wire core as a heating element. Since the resistance per unit length of the wire core and the passing current are constant, the entire heating belt is heated evenly from end to end, and the output power is constant. Its biggest feature is its long length of use, which is mainly suitable for heating and heat preservation of single pipelines of long and ultra-long length. The maximum length of the power point is from several hundred meters to several thousand meters.

Since commissioning, our high-aromatic oil-electric heating system has fully satisfied the compensation of the pipeline's heat loss and achieved the expected energy saving effect. In addition, electric heating has high thermal efficiency and simple design. Simple installation, no pollution, long service life, energy saving, automatic control and other advantages, it is an important way for channels to replace steam heating and hot water heating. In an external pipe latent hazard control project, long-length pipelines such as px pipelines and acetic acid pipelines can use the same type of electric heating system.

Next Article

Latest News