Electrical heating of the compressor pipeline in the associated petroleum gas zone

Published on:

2022-10-08 17:00

As an effective insulation of pipelines and antifreeze, electric heating is widely used in petroleum, petrochemical, chemical and other industries. The heating is to use the outside world to supply heat to a pipeline or equipment. When the heat generated is equivalent to that of a pipeline or equipment, the pipeline can maintain a relatively constant temperature at that temperature. This method of supplying heat from the outside to pipelines or equipment is electric heating.

Heating can be divided into three forms: 1. Steam heating is called steam heating with steam as heat medium 2. Electric heating is called electric heating with electricity as energy source Water heating.

Compared with steam heating, electric heating has attracted more and more attention from users due to its advantages of accurate temperature control, high heat transfer efficiency, easy installation, convenient operation and maintenance, etc. D.

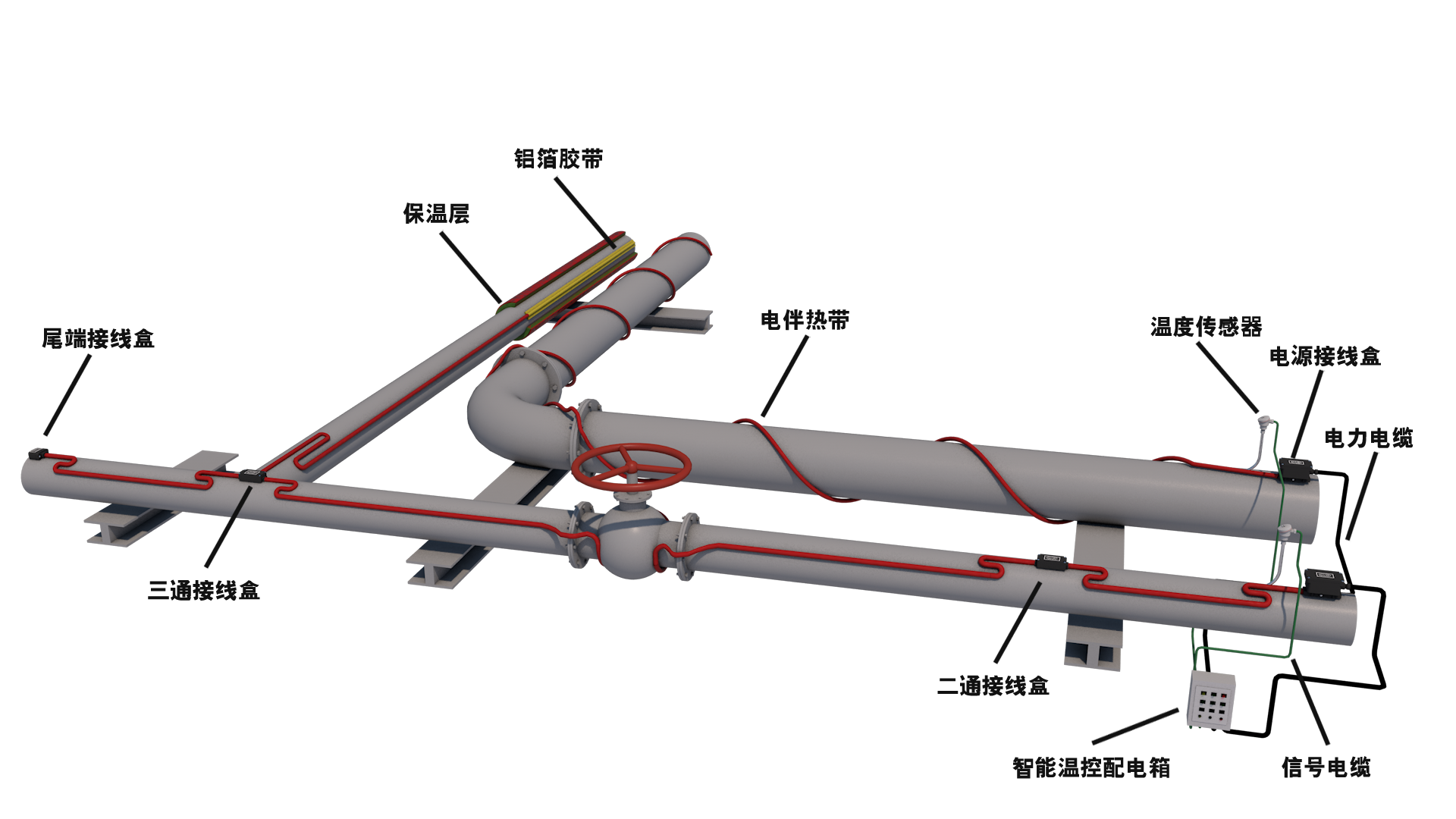

The electric heating system of the pipeline consists of a heating cable, a power junction box, a terminal junction box, a heat shrinkage kit, a temperature sensor, mounting accessories and other materials.

This article considers, as an example, the electric heating of compressors pipelines in the associated petroleum gas production area to represent the entire process of designing electric heating pipelines. In 2010, we delivered a batch of electric heating cables to an oil-producing country in the Middle East. The proven reserves of the field's oil amount to about 2.8 billion barrels, natural gas reserves-70 billion cubic meters, its development is planned to be carried out in four stages. The central technological station of the field carries out the main technological processes, such as oil and gas separation, desalination and drying, pressure increase and external transport in the first stage of field development. Among them, crude oil is transported to other pressure-raising stations via pipeline after three-phase separation, heat exchange, delay, stabilization and other processes at the preparation station.

The main function of the associated gas compression zone with heavy oil is to receive gas from the heavy oil zone, separate it with an advanced buffer tank, then feed it into the compressor for boost, and finally transport it to the commercial gas zone after cooling. Air cooler. Including two compressor installations, one working and one backup. To prevent damage to the compressor due to gas entrainment, electric heating has become an extremely important task.

At present, the field electric heating has been in operation for two years and is in good condition.

Next Article

Latest News