Self-regulating electric heating cables are used to prevent freezing of the pipelines of chemical plants.

Published on:

2023-02-16 16:23

Heating of pipelines in chemical plants is an effective measure to prevent freezing of pipelines in winter. Commonly used forms of heating include steam and electric heating. Steam heating is a traditional and main way to preserve heat. Its principle is to dissipate heat through steam heating pipes so as not to lose heat from insulated pipes. It has the advantages of small investment and large heat supply, but the energy consumption is large, the pipeline is easily corroded and leaking, and the maintenance cost is high; electric heating is a technology, Which has been widely promoted in recent years, and investment in construction is high, but difficult to operate. The cost of maintenance is low, and so far the development has been very mature.

Take the gas field treatment plant in northwest China, for example. The electric heating cable is applied to the small diameter technological pipeline. The company replaced the liquid level and differential pressure gauges of the desulfurization column, the draining column and the regeneration tower, and the steam heating crude oil pipelines in the instrument box of the additional steam and evaporation column with electric heating. Dismantling about 300 m of heating and return water pipelines, as well as reinstalling and laying two electric heating lines with a total length of about 300 m. The power distribution line leaves the electricity distribution room, is connected to a newly installed special electric heating distribution box, and then the junction box distributes the electric heating at each point of the distribution line.

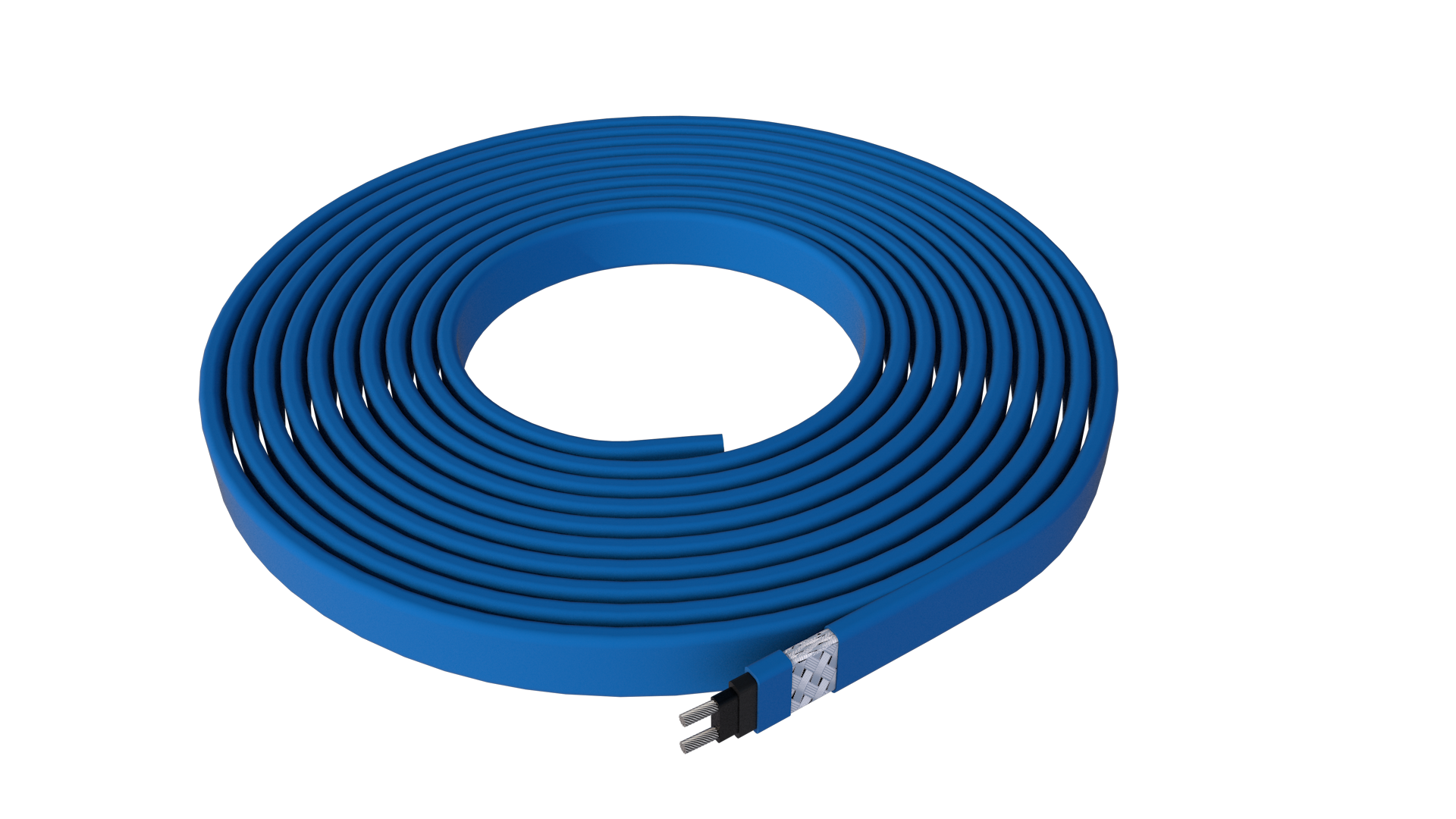

Self-heating self-regulating electric heating cables series are widely used in fire, oil, chemical, metallurgical, electric power, environmental and other industrial plants for heating, heat preservation, anticoagulation and anti-freezing of pipelines and storage tanks. The electric heating tape is suitable for common areas, hazardous areas and corrosion zones. After use together with the explosion-proof power distribution box, it is suitable for the explosive gas mixture "T3, T4, T6" of the groups of places of the first and second sections of the factory, which are not directly affected by external forces.

Self-regulating electric heating cable parameters

(1) Standard color: Black/Blue

(2) Temperature range: The maximum operating temperature is 65 ± 5 °C and the maximum temperature to be sustained is 90 °C.

(3) Design temperature: Polyolefin minimum-20 °C, Fluorine material minimum-60 °C

(4) Start current: ≤ 0.5 A/m

(5) Thermal stability: After the electric heating belt has passed the thermal performance test, its power should be maintained at 90% of the original value.

(6) Bending radius: 25.4mm at-20 °C, 35mm at-60 °C

(7) Insulation resistance: The insulation resistance between the electric heating conductor and the metal shielding layer shall not be less than 50 MOM.

Self-regulating temperature electric heating cable is easy to install, easy to maintain, works all day, has a high level of automation, low operation and maintenance costs, can be arbitrarily shortened or extended within a certain range, allows for multiple overlapping without high temperature. Hot spots and anxiety about fires. Thus, self-regulated temperature electric heating is very suitable for pipelines with short distances and a large number of flange pump valves.

Previous Article

Latest News