Application of electric heating in the water supply pipeline of the aggloplant

Published on:

2022-09-06 16:28

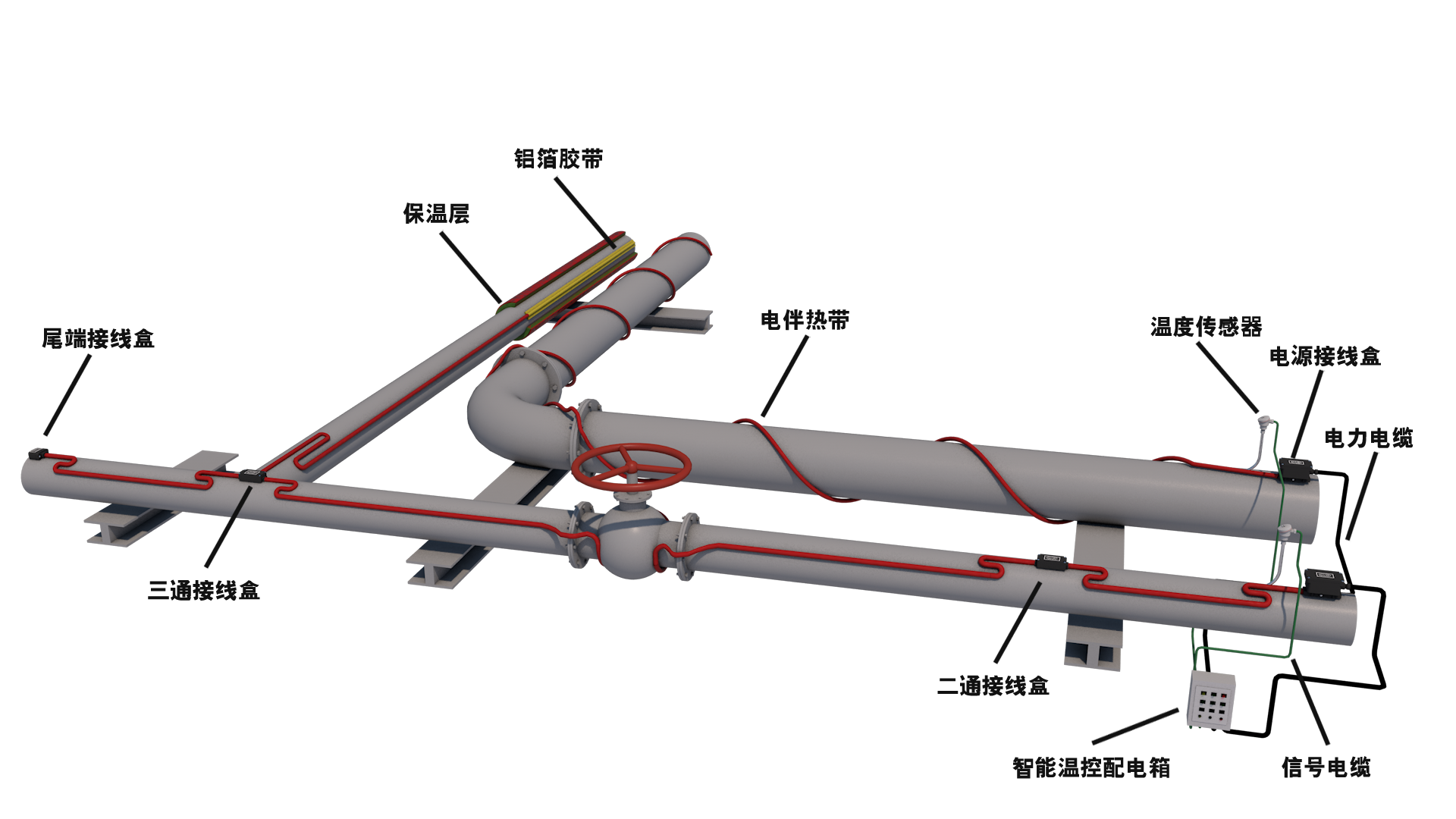

In the actual production of industrial enterprises, process pipelines are mainly heated by steam or hot water. However, in the traditional electric heating method, it is often difficult to control heat dissipation, and the heat preservation efficiency is low. With the development of science and technology and the development of modern industry, electric heating technology has been widely used in various fields such as metallurgy, chemical industry, oil and electricity, due to its remarkable advantages.

Electric heating cables fall into two categories: variable power and constant power. The variable power heating cable consists of a conductive material, two parallel tires and an insulation layer. Its characteristic is that the conductive material has a high positive temperature coefficient of resistance, and the output power can be automatically adjusted when the ambient temperature changes.

When the heating wire is in a lower temperature environment, the conductive material is compressed to connect the carbon particle molecules, forming a circuit to allow the current to pass through, and the heating wire is heated; and when the heating wire is in a higher temperature In the environment, the conductive material begins to expand and disperse the carbon particle molecules, As a result, the circuit is interrupted. When connected to the power supply, all temperature control is done by automatically adjusting the material's own characteristics. The temperature is relatively stable and will not be too high or too low.

The heating capacity per unit length of constant power electric heating is constant, and the temperature cannot be adjusted automatically. According to the connection mode of the resistive wire, it can be divided into two types: parallel type and serial type. In the first case, the resistance wires are connected in parallel and can be cut at will; in the case of a series constant power heating cable, the resistance wires are connected in series and cannot be cut.

On the example of the project of the new aglofactory of the steel mill in 2020, the area of the agglomeration machine is 450 m2, and the design scale is 463 m2 of finished aggler per year. 30,000 tons. All external pipes for the production water supply in the area of the sintering factory are equipped with electric heating to prevent freezing. On the example of heat saving of a 100-meter pipeline of industrial water supply at the plant, an economic and technical comparison of steam and electric heating is carried out. Among them, the steam pipeline uses the DN20 heating steel pipe according to the technological requirements, the total length of 100 m, and the electric heating uses a variable power electric heating tape with a voltage of 220 V. In the course of actual operation, the plant found that compared to the cost of electric heating and steam heating, the first is more expensive than the second. 89% electric heating advantage is significant.

Although the initial investment in the electric heating process is relatively high, operating costs are significantly reduced compared to other forms of heating, and the economic benefits are significant. Judging by the current domestic operation of the aglofactories, which have adopted electric heating systems for heating, the electric heating systems are working normally after commissioning, the heating effect meets the design requirements, and the heating temperature is stable, which can fully meet the process requirements.

At the same time, compared with traditional steam heating, it eliminates the phenomenon of "work, ejection, drip and leak", obviously improves the production environment of the enterprise and increases the economic benefits of the enterprise. It can be predicted that in the thermal insulation applications of the metallurgical industry, electric heating will replace steam and water heating and become the main method of technological heating, which will become an inevitable trend.

Latest News