Product Details

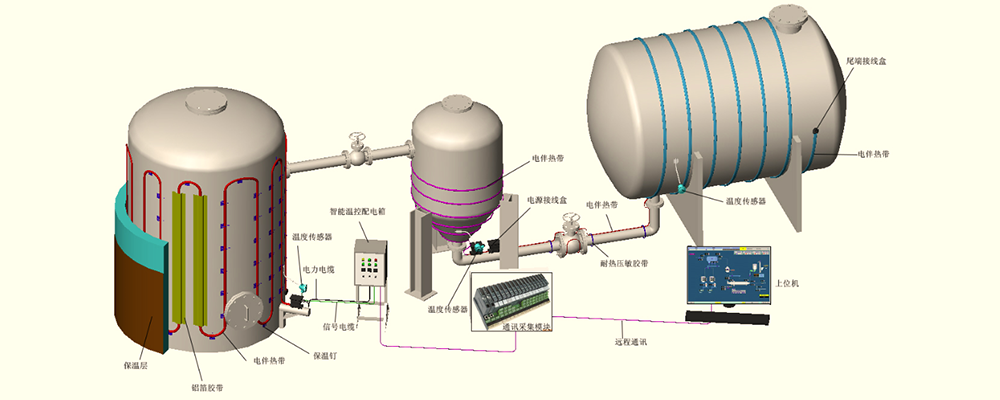

Electric Tank Heating System

Working Principle The tank temperature sensor sends the measured temperature to the temperature control meter in the intelligent temperature control box via the signal cable, and the temperature control meter compares the obtained temperature with a given temperature, and the current temperature is above the set. Temperature When the current temperature is lower than the set temperature, the electric heating does not work. To avoid frequent starts, hysteresis is usually set. The junction box can also be connected to the central control room or DCS system by remote control. Communication., can remotely observe and control the start and stop of the electric heating cable. Construction and installation When laying the electric heating cable on the tank body, the surface of the tank body must first be ironed, and then a layer of wire mesh must be laid on the tank body (or insulating nails must be glued on the tank body, or the hooks must be welded to the tank body, etc. D.), and finally, an electric heating cable should be installed. After the heating cable is installed, cover it with a layer of aluminum foil along the direction of the electric heating cable to increase the heating area of the tank. The installation distance is obtained by calculating the heat dissipation and surface area of the tank. In Atlas 16C401. |

|

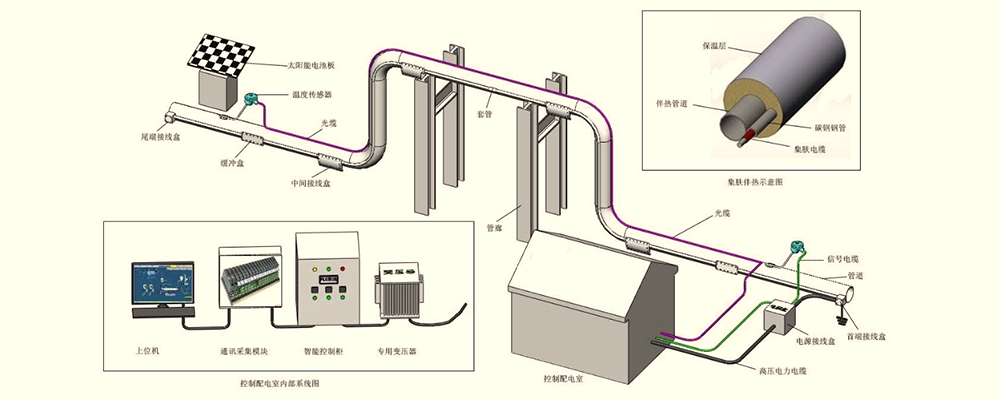

Electric skin heating system

|

Working principle Skin heating is mainly realized by "skin effect" and "proximity effect" AC. The so-called skin effect is a phenomenon in which alternating current passes through a carbon steel conductor, The current gradually tends to the skin to the surface of the conductor. The proximity effect is the electromagnetic phenomenon between a pair of electrical bodies with opposite currents. When the current passes between the cable in the heating pipe and the heat pipe, heat is the heat needed for heating. Construction & Installation Weld the carbon steel pipe and pipe together, insert the sheathing cable into the carbon steel pipe, short-lock the carbon steel pipe and sheathing cable at the end, and connect the power supply to the first end. The gap between the carbon steel pipe and the pipe is filled with heat transfer cement to increase the heat dissipation area. Since the skin tracer heat pipe is usually several kilometers long, the requirements for signal transmission and power supply are extremely high in this case. Remote communication is via fiber optic or PLC system. |