Product Categories

Skin Trace Series

Depending on the different substances of the liquid in the pipeline, the temperature maintained in the pipeline is also different. The electric heating technology of the industrial frequency surface effect pipeline is mainly used for heating the pipeline and heating, melting or intermittent transportation of oil.

Keywords:

Series:

Product Details

1. Application Brief

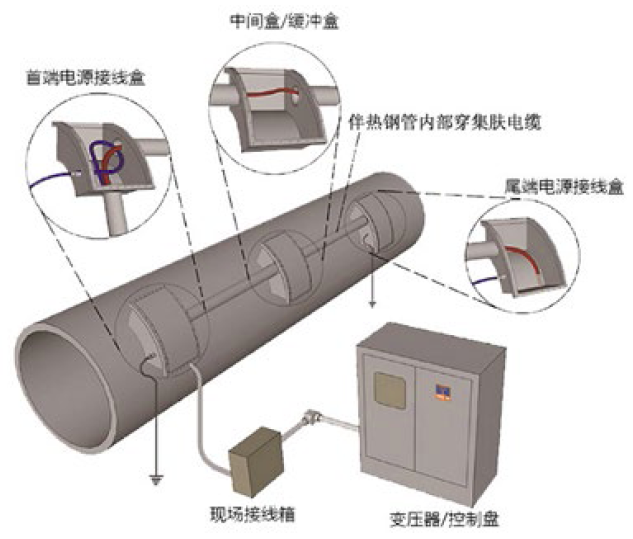

Depending on the different substances of the fluid in the pipeline, the temperature maintained in the pipeline is also different. The industrial frequency surface effect electric heating pipeline technology is mainly used for heating the pipeline and heating, melting or intermittent transportation of oil. Liquid or solidified medium in the pipeline. There are two ways to collect the skin inside the tube and collect the skin outside the tube.

① Oil fields, offshore platforms: production pipelines, crude oil, steam pipelines, water pipelines, pulse lines, instruments, storage towers at centralized stations, main pipelines, etc. D. The bottom of the river, the bottom of the lake, the underwater oil pipeline.

②, refining industry, distillation, hydrocracking, coking, paraffin, vulcanization, asphalt, residual oil and other production pipelines, water pipes, pulse lines or tools, storage towers, liquid hydrocarbon storage towers.

③Petrochemical plants, chemical plants, chemical fertilizer plants: benzene, styrene, polyethylene, chlorine, acrylic acid, oxalic acid, ethylene glycol, phthalic aldehyde, synthetic fiber, nylon, dye paints, resins and other production pipelines; Water pipes, pulse lines or meters, storage towers, Liquid hydrocarbon storage towers.

④ Nuclear power plants: heavy water pipelines, water pipes, pulse lines and appliances, water towers, heavy water towers.

⑤ Petroleum pumping station: oil storage towers, trunk pipelines, low-temperature oil product tower foundations, and pipelines and water lines connected to towers.

⑥ Power plants: high pressure water supply, wastewater ventilation, steam, degassing, high pressure condensation, acid-alkali, oil pipelines for fuel oil storage and other pipelines, fuel oil pipelines, fuel oil towers, pulse lines and appliances, water pipes, main pipelines, tubing for transportation of water-coal sludge, etc. D.

⑦ Metallurgical plant: production pipelines, fuel oil, coal tar, asphalt and sulfur, water pipes, main pipelines.

⑧ Cement Plant: Furnace or fuel oil line, water pipe, pulse line or tool, storage tower, fuel oil main line.

⑨, There are also plastics processing plants, edible oil processing plants, chocolate processing plants, water supply plants, hotels and high-rise buildings, and heavy engineering industries.

Heating skin: It can be divided into two types: external skin and internal skin. The above-mentioned different types of pipeline transport can use electric heating on the skin effect.

It is concluded from practice that this technical solution has achieved good transport effects and significant economic benefits.

\ \ n2 \ nSetting Example Skin